WEIGHING

AND SAMPLING STATIONS

WEIGHING STATIONS

Protect your operators and raw materials with our weighing booths

Handling volatile substances can pose significant health risks to your staff.

The weighing stage, in particular, carries a high risk of contamination due to airborne particles and bio-contaminants (bacteria, fungi, viruses, etc.).

Installing high-performance filtration systems is therefore essential to mitigate these risks.

The concept of localized protection refers to equipment installed as close as possible to the critical area whether in a polluted industrial environment or in a cleanroom setting.

Localized Protection Solutions

Since 1989, Euroflux has been designing and manufacturing equipment in France dedicated to the control of airborne particles and bio-contamination.

Our weighing booths are part of these protective solutions.

They ensure triple protection against contamination of:

– The operator

– The product

– The surrounding environment

Our standard and custom-built solutions are designed to meet your needs, regardless of your available space or configuration, while complying with ISO 14644 standards.

From project design to installation and commissioning, you benefit from a single point of contact throughout your project.

OUR RANGE OF WEIGHING STATIONS

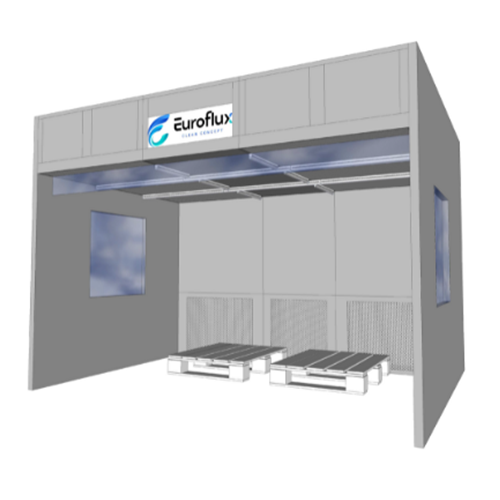

Fresh Air Weighing Booths

Combination of a supply plenum and an exhaust column.

Provides triple protection with the filtered air discharged to the outside ideal for handling CMR or ATEX-risk materials.

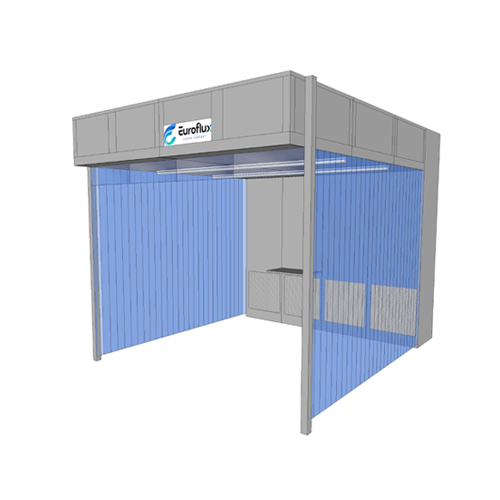

Recirculating Weighing Booths

Combination of a supply plenum and an exhaust column.

Provides triple protection without discharging filtered air to the outside.

Custom Weighing Booths

Configurable to your specific requirements, with available options such as audit trail systems, motorized mobility, and more.

Ergonomics, Safety and Efficiency

In addition to our standard models, we design custom weighing booths tailored to your technical and ergonomic needs, ensuring the comfort and safety of your teams.

For over 35 years, our mission has been to design and manufacture in France equipment with low environmental impact.

We pay special attention to the durability, modularity, and energy efficiency of our manufactured products.

The innovative design of our weighing stations ensures full Emery test compliance throughout their operational life.

Our technical teams strictly follow all applicable standards and regulations.

Ergonomics, Safety and Efficiency

In addition to our standard models, we design custom weighing booths tailored to your technical and ergonomic needs, ensuring the comfort and safety of your teams.

For over 35 years, our mission has been to design and manufacture in France equipment with low environmental impact.

We pay special attention to the durability, modularity, and energy efficiency of our manufactured products.

The innovative design of our weighing stations ensures full Emery test compliance throughout their operational life.

Our technical teams strictly follow all applicable standards and regulations.

Discover Our Range of Weighing Booths

THE ADVANTAGES OF OUR WEIGHING BOOTHS

Easy Filter Access: Grilles and prefilters (G4/F7) can be removed without tools.

Long-Term Reliability – Emery Test Approved: Guaranteed static and dynamic airtightness.

Touchscreen Control System: Centralized monitoring and operation via an intuitive HMI display.

Each Weighing Booth Consists of Four Key Components:

- Modul’air

Thanks to the piston effect of the laminar airflow, the Modul’air system ensures complete operator and product protection across the entire work area.

Standard filtration: H14

Optional: U15 to U17 on request

- Filtration on recovery

An efficient prefiltration system extends the service life of H14 absolute filters.

Standard: G4 + F7 prefilters

Optional: M5 to F9 prefiltration or absolute filtration

Optional: Bag-In/Bag-Out (BIBO) maintenance housing for safe filter replacement

- Laminar Airflow Guidance

Ensures proper containment and protection of both the product and the operator.

Flexible guidance using strip curtains

Rigid guidance using panels (Plexiglas, stainless steel, etc.)

- Weighing Booth Structure

Self-supporting design with structural posts

Suspended design (no posts), fixed with threaded rods on existing supports

Motorized version available for mobile configurations

Discover Our Range of Weighing Booths

THE ADVANTAGES OF OUR WEIGHING BOOTHS

Easy Filter Access: Grilles and prefilters (G4/F7) can be removed without tools.

Long-Term Reliability – Emery Test Approved: Guaranteed static and dynamic airtightness.

Touchscreen Control System: Centralized monitoring and operation via an intuitive HMI display.

Each Weighing Booth Consists of Four Key Components:

- Modul’air

Thanks to the piston effect of the laminar airflow, the Modul’air system ensures complete operator and product protection across the entire work area.

Standard filtration: H14

Optional: U15 to U17 on request

- Filtration on recovery

An efficient prefiltration system extends the service life of H14 absolute filters.

Standard: G4 + F7 prefilters

Optional: M5 to F9 prefiltration or absolute filtration

Optional: Bag-In/Bag-Out (BIBO) maintenance housing for safe filter replacement

- Laminar Airflow Guidance

Ensures proper containment and protection of both the product and the operator.

Flexible guidance using strip curtains

Rigid guidance using panels (Plexiglas, stainless steel, etc.)

- Weighing Booth Structure

Self-supporting design with structural posts

Suspended design (no posts), fixed with threaded rods on existing supports

Motorized version available for mobile configurations