LAMINAR AIRFLOW

PRINCIPLES

Laminar Airflow Principles

Why Use Laminar Airflow?

Laminar airflow systems are designed to control airborne contamination such as:

- Dust

- Visible and invisible particles

- Bio-contaminants (bacteria, fungi, viruses, etc.)

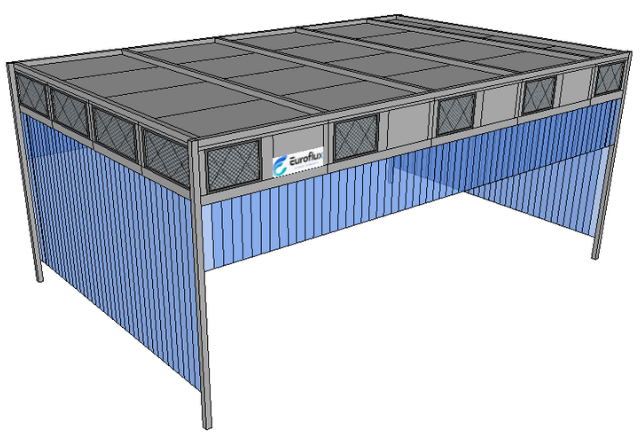

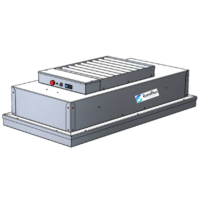

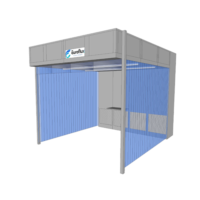

They are widely used across industrial, hospital, and laboratory environments, and are installed as close as possible to the process area whether in an industrial workspace or a controlled environment (cleanroom or grey room).

What Is Laminar Airflow?

A laminar airflow is a unidirectional, non-turbulent flow of air in which air velocity remains uniform across the entire blowing surface.

It is defined by the following velocity criteria:

Vavg – 20% ≤ Vindividual ≤ Vavg + 20%

The typical target airflow velocity is 0.45 m/s.

Laminar airflow systems are tested in accordance with ISO 14644-3, creating a piston effect that pushes contaminants away from the protected area unlike turbulent airflow, which increases the risk of cross-contamination.